Unit Roller485-Lite

SKU:U182-Lite

Description

Unit Roller485-Lite is a brushless DC motor motion execution kit with integrated control functions, designed for efficient motion control. The product supports 6-16V DC power input (via the PWR485 interface) or 5V input (via the Grove interface), and can automatically adjust the power coefficient to ensure optimal performance. It features a built-in FOC closed-loop drive system, using a 3504 200KV brushless motor, with a maximum continuous phase current of 0.5A and a short-term current of 1A without forced cooling. The driver uses a magnetic encoder as feedback, supporting current, speed, and position triple-loop control to ensure precise control.

Additionally, the device is equipped with a 0.66-inch OLED display on the back to show real-time device status, and includes RGB indicators and function buttons for easy human-machine interaction. The product base is designed with LEGO-compatible mounting holes and M3 screw holes for quick assembly and integration. The Unit Roller485-Lite is fully open-source in both hardware and software, supporting motion control and parameter adjustment via RS485 or I2C buses, and provides SWD and SWO debugging interfaces to further enhance developer flexibility. This product is used in robotic joints, motion control, industrial automation, and visual demonstration projects.

Learn

Features

- Brushless DC motor control

- RS-485 communication / I2C communication control

- Integrated OLED display

- RGB indicators

- FOC closed-loop drive system

Includes

- 1 x Roller485 Lite Unit

- 1 x HT3.96-4P connector

- 1 x HY2.0-4P Grove cable (5cm)

- 6 x Friction pins

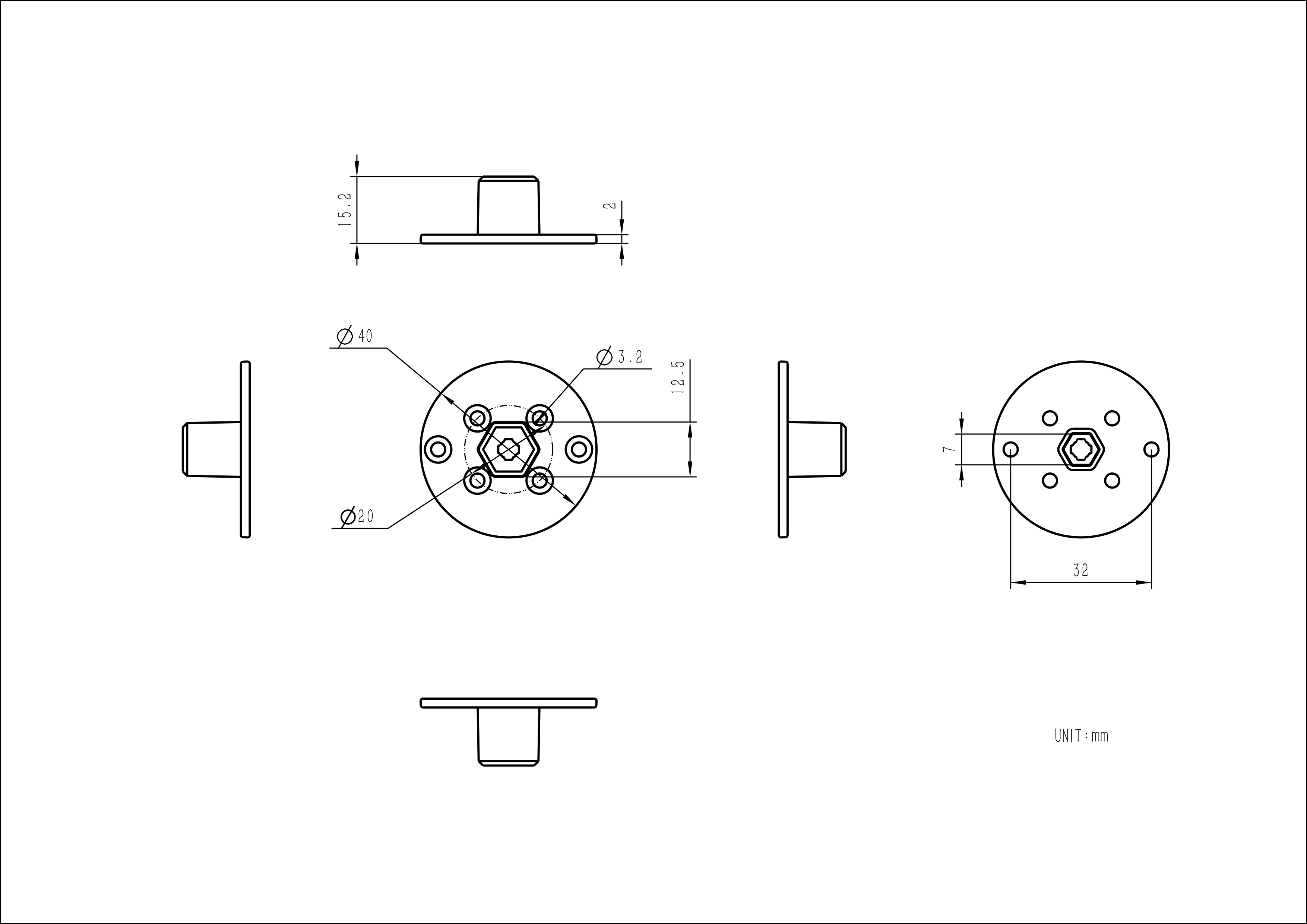

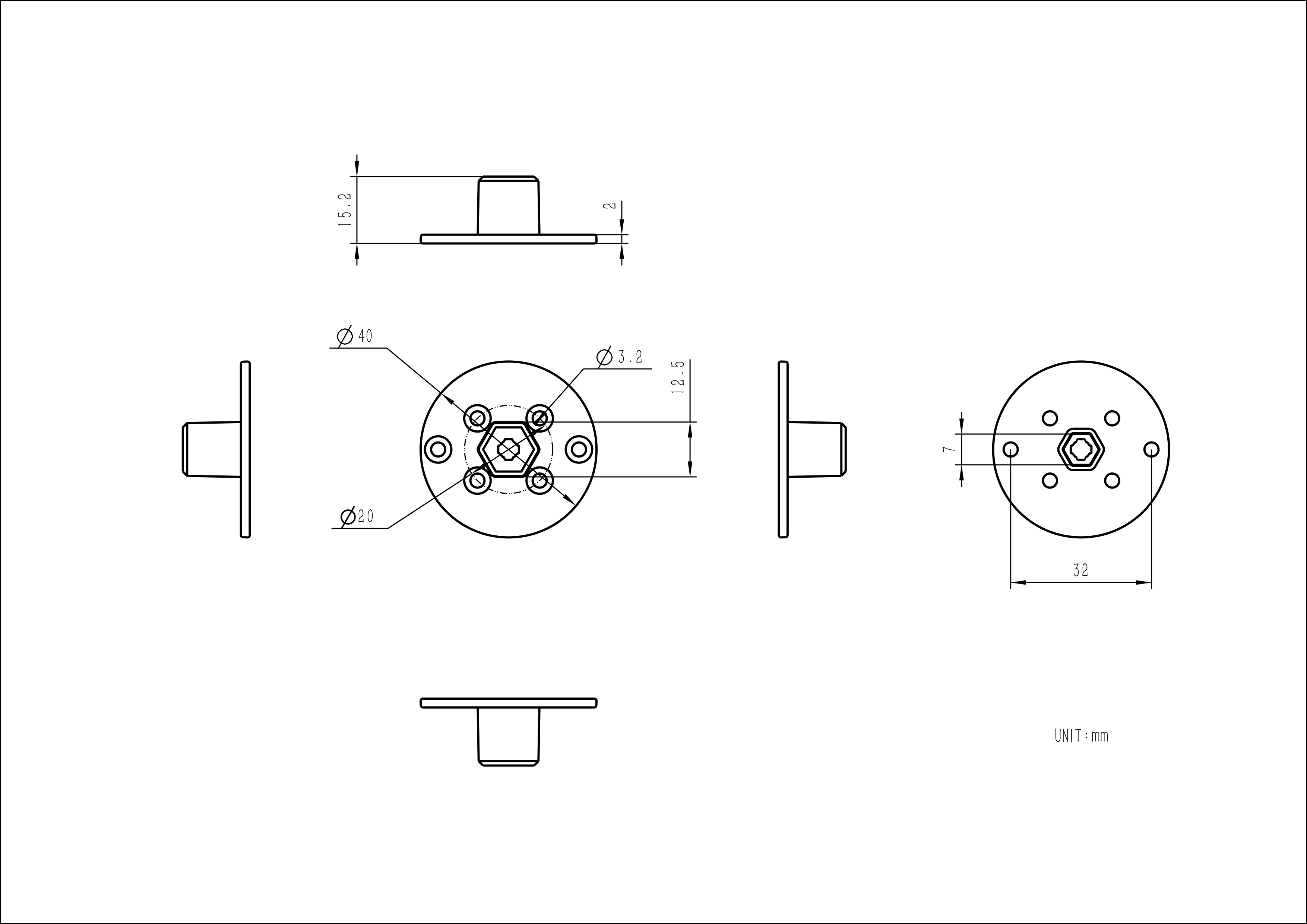

- 1 x Flange

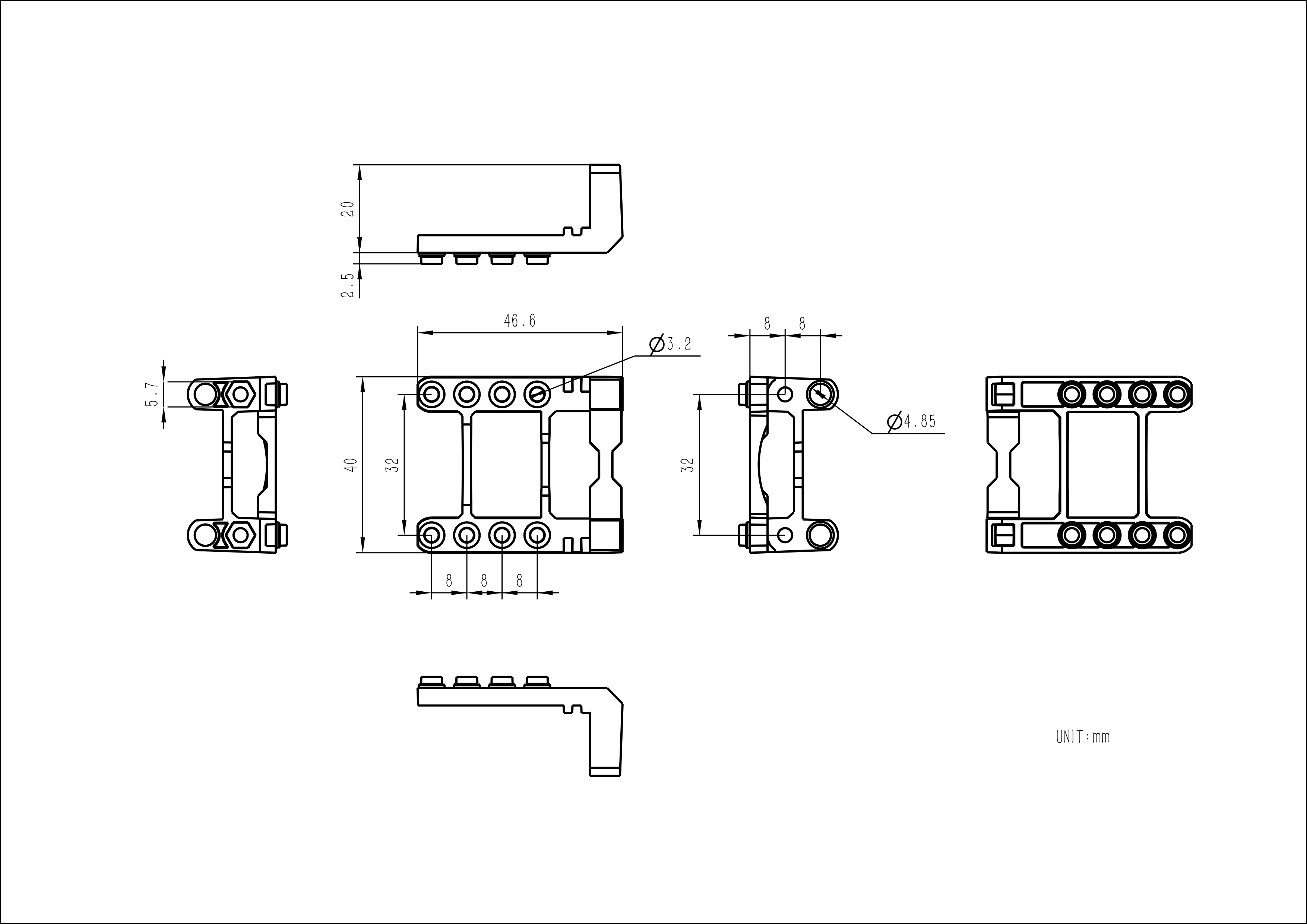

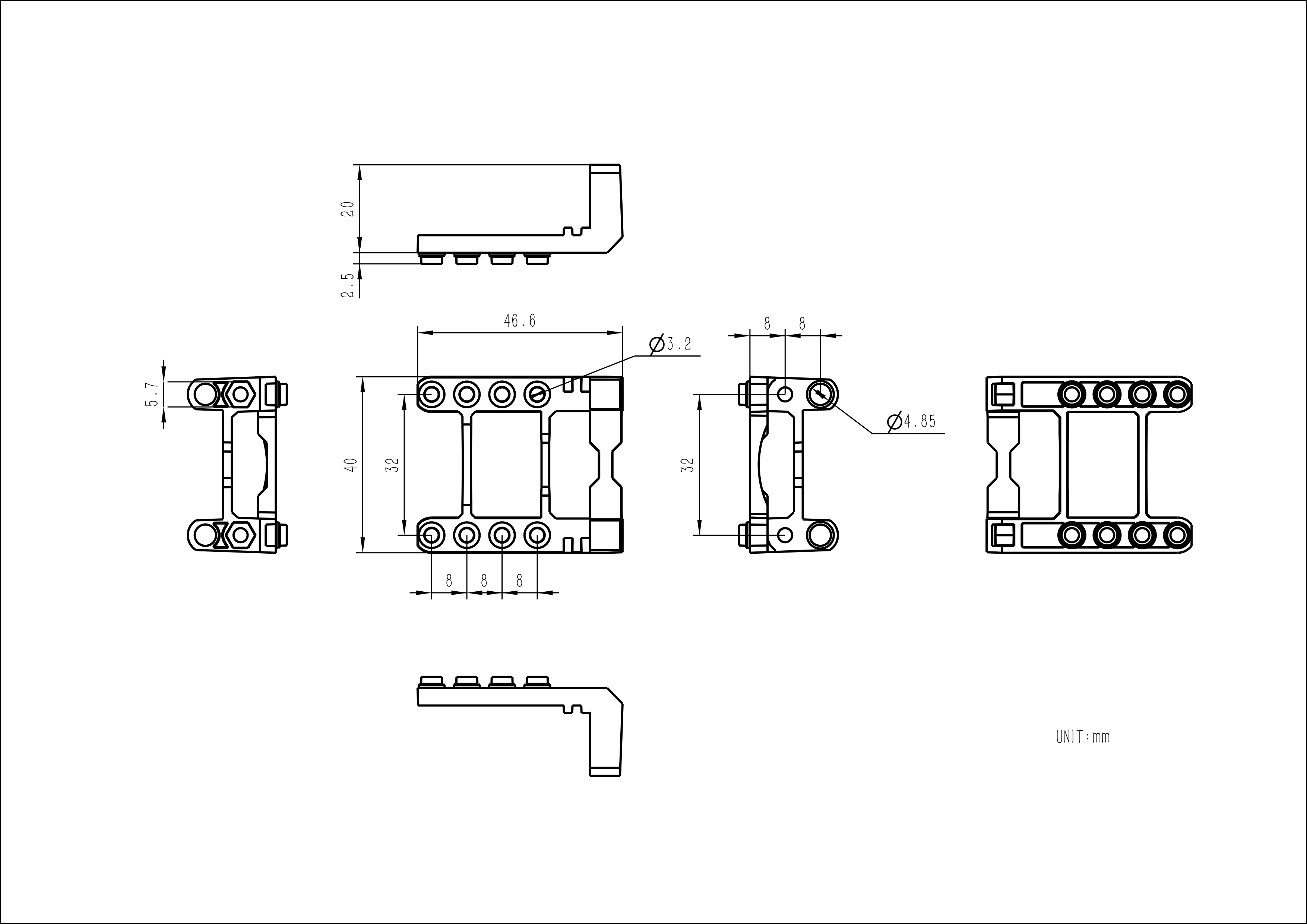

- 1 x Bracket

- 1 x Motor Mounting Plate

- 1 x Hex key (2.5mm)

- 1 x Hex key (2mm)

- 6 x M3 nuts

- 2 x Hex socket head M3x14mm screws

- 4 x Hex socket head M3x14mm screws

- 2 x Hex socket head M3x12mm screws

- 4 x Hex socket head M3x5mm screws

- 1 x Single-ended terminal wire 5P debug cable

Applications

- Robotic joint control

- Smart manufacturing equipment

- Visual demonstrations

Specifications

| Specification | Parameters |

|---|---|

| MCU | STM32G431CBU6@Cortex-M4, 128KB-Flash, 32KB-SRAM, 170MHz |

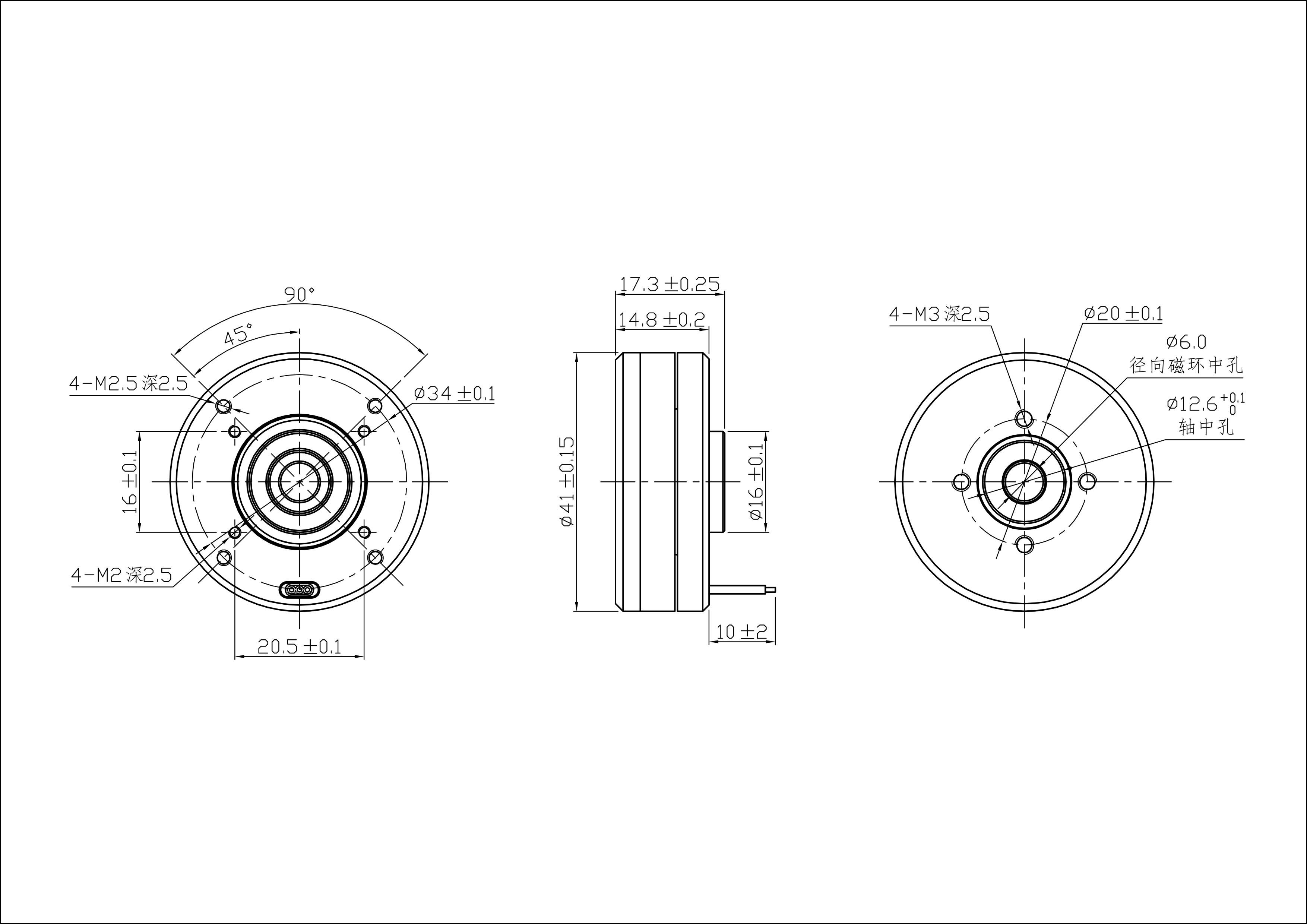

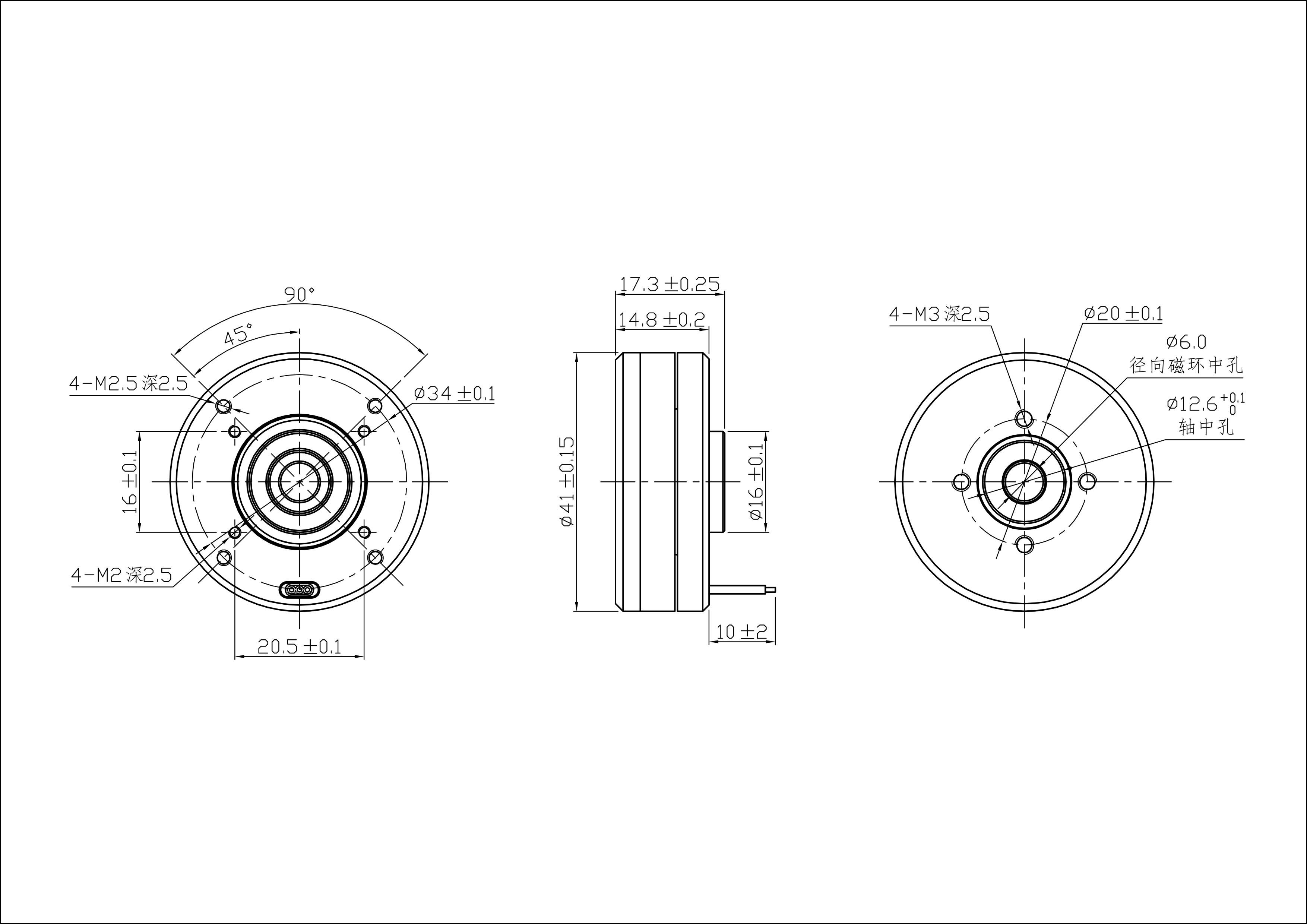

| Motor Type | D3504 200KV brushless motor@diameter: 41mm |

| Driver Chip | DRV8311HRRWR |

| Angle Sensor | TLI5012BE1000 |

| Communication Interfaces | 1x PWR-485 (HT3.96-4P interface) 1x I2C (0x64) |

| Display | 0.66-inch OLED display, resolution: 64 x 48, SPI communication |

| RGB LEDs | 2x WS2812-2020 |

| Motor Power | RS-485 (HT3.96-4P interface) power@6-16V Grove port DC 5V power |

| Load | Load: 50g, Motor speed: 2100rpm, Current: DC 16V/225mA Load: 200g, Motor speed: 1400rpm, Current: DC 16V/601mA Load: 500g (maximum load), Motor speed: 560rpm, Current: DC 16V/918mA No load: DC 16V/78mA |

| Standby Current | Grove port DC 5V power@70mA RS-485 (HT3.96-4P interface) power DC 16V@32mA |

| Noise | 48dB |

| Output Torque | Grove port DC 5V power: 0.021N.m/0.2kgf.cm@current 350mA RS485 (HT3.96-4P interface) power: 0.065N.m/0.66kgf.cm@current 927mA |

| Operating Temperature | 0 ~ 40°C |

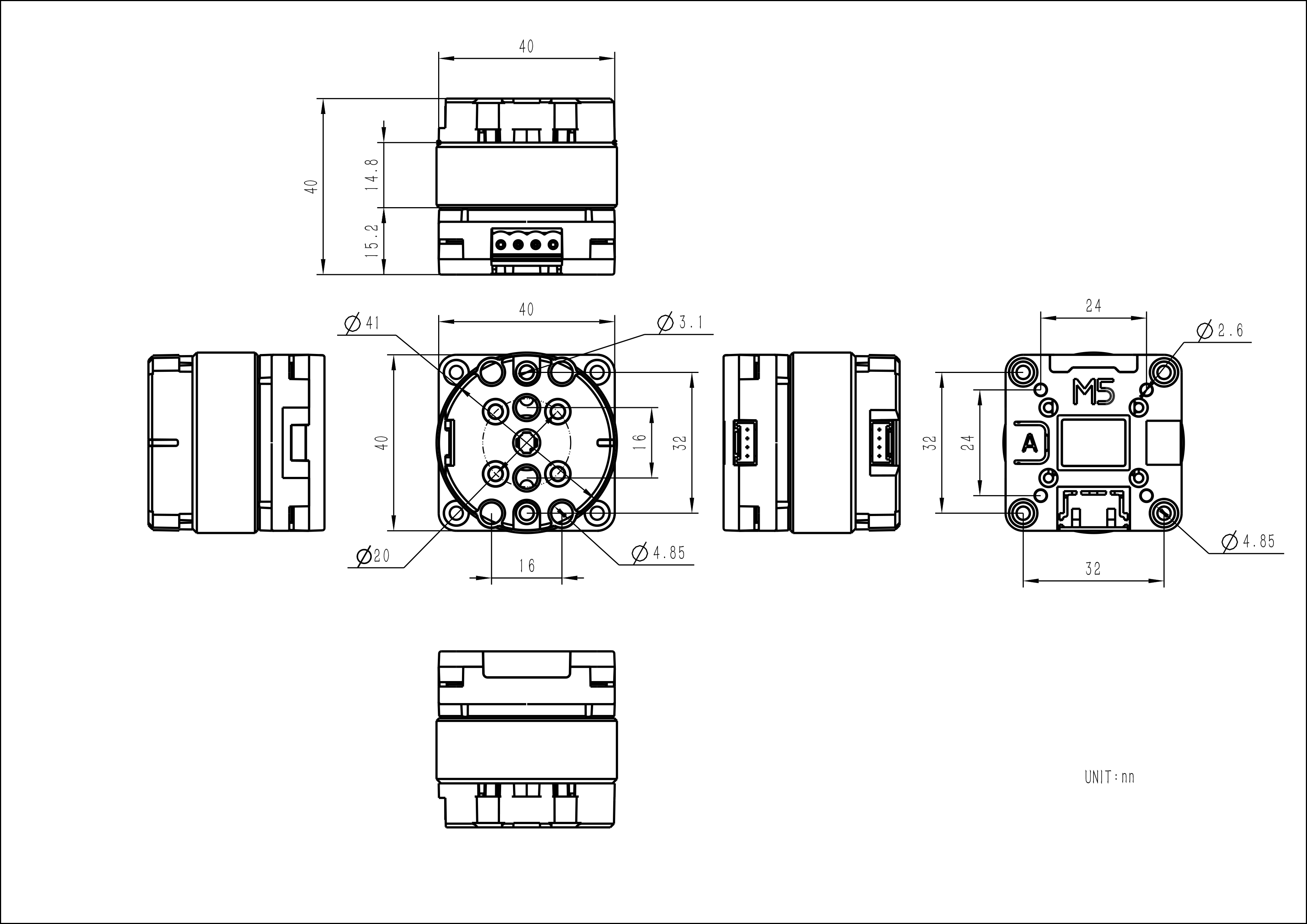

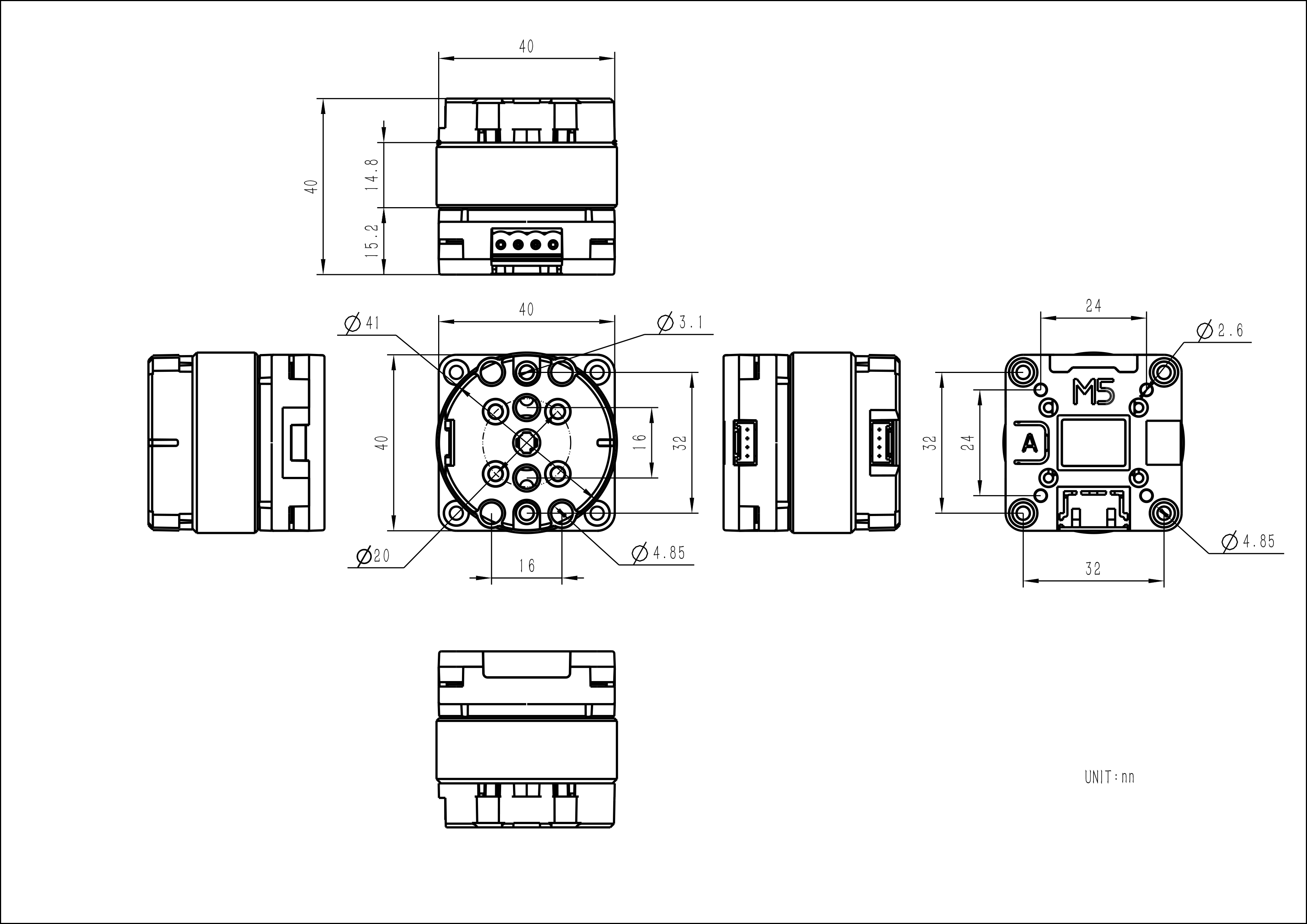

| Product Size | 40.0 x 40.0 x 40.0mm |

| Product Weight | 71.0g |

| Package Size | 105.0 x 76.0 x 54.0mm |

| Gross Weight | 151.0g |

Learn

Schematics

PinMap

Unit Roller485-Lite

| HY2.0-4P | Black | Red | Yellow | White |

|---|---|---|---|---|

| PORT.A | GND | 5V | SDA | SCL |

I2C, PWR485, RGB, Button

| STM32G431CBU6 | PA15 | PB7 | PC11 | PC10 | PB4 | PB5 | PA12 |

|---|---|---|---|---|---|---|---|

| I2C | SYS_I2C_SCL | SYS_I2C_SDA | |||||

| PWR485 | RS485_RX | RS485_TX | RS485_DIR | ||||

| WS2812C | LED_DAT | ||||||

| Button A | SYS_SW |

OLED

| STM32G431CBU6 | PB15 | PB13 | PB14 | PB11 | PB12 |

|---|---|---|---|---|---|

| OLED | OLED_MOSI | OLED_SCK | OLED_DC | OLED_RST | OLED_CS |

Model Size

Datasheets

Softwares

Arduino

Internal Firmware

Communication Protocols

I2C Protocol

RS485 Protocol

Video

- Unit Roller485-Lite Product Introduction and Case Demonstration